Special tapes

SwissBeltService offers a wide range of conveyor belts for a variety of industries and applications.

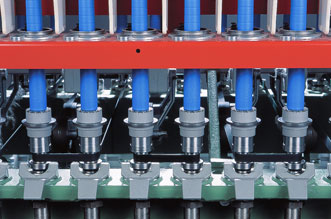

SwissBeltService’s spindle belts have been setting standards in their field for decades and are in demand from customers all over the world. W spindle belts were developed in close collaboration with a leading machine manufacturer. The belts can handle spindle speeds of over 20,000 rpm without accumulation of fiber fly and offer high and reliable mileage.

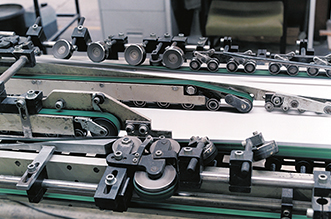

Machine belts play a central role in manufacturing processes. They transport, accelerate, slow down, position and fold the paper to be processed if necessary.

The Hamid, polyamide and polyurethane machine belts from SwissBeltService’s extensive range are manufactured with abrasion-resistant NBR cover coverings or other application-specific surface materials. They provide the industry with effective and comprehensive tape solutions that are extremely reliable and offer consistent adhesion with a long service life.

The conveyor and process belts are available with a variety of application-oriented covering materials and surface structures as well as in various industry-standard colors. Materials and designs have been chosen to cover a wide range of application requirements, including resistance to wear and chemicals as well as high or low temperatures. In addition, the use of carefully selected tension members maintains their excellent stress-strain behavior.

While the term “conveyor belt” is used for belts that transport goods from A to B, the term “process belt” refers to belts that also perform key functions in the manufacturing process.

Typical examples of this are printing blankets for textile printing.

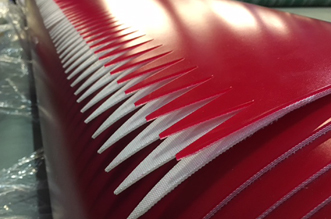

SwissBeltService punching belts have been specifically developed for first-class oil resistance, mechanical stability and abrasion resistance, making them extremely durable and reliable. The scratch resistance of the belt surface is a key feature that guarantees longer belt life, less downtime and reduced costs.

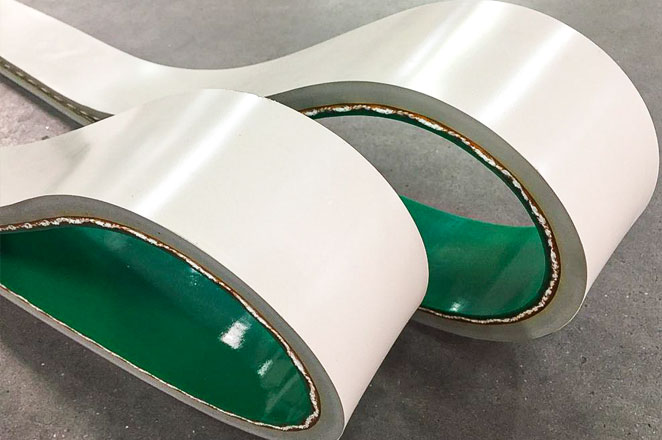

Curve belts are custom-made products in all sizes for your curve systems with the common belt guidance systems for all industrial sectors. We assemble according to your drawing or based on a sample tape provided.

Our know-how, combined with modern manufacturing options, allows us to achieve short delivery times, from one day to the next in an emergency.

Curves are tailor-made from one or more segments and are used in a clockwise or counterclockwise direction. Designs at an angle of 30° to 180° with different tape guide systems such as rollers, eyelets, loops, strips and elastic strips are possible.

Our curved belts can be manufactured in special dimensions, in a wide variety of belt qualities and with a large selection of profiles on the supporting side. They meet a wide variety of requirements and have proven themselves in many industries.

Pull-off belts with back coatings made of PVC, PU, rubber or silicone have been used successfully for years in the profile and plastic extrusion industry as well as in the cable, pipe and wire industry. The material structure of our trigger belts always corresponds to the latest experience and requirements of our customers. Trigger slings are characterized by endlessly woven/wound, seamless tension members. This results in excellent running properties and the long service life of our products. For unusual applications, we also offer special coatings with processing according to your wishes.

The endlessly woven/wound polyester inserts of our trigger belts result in great flexibility and high dimensional accuracy, which enable them to be used even with small deflections.

If necessary, trigger belts can be precisely ground to an even thickness. Special profiles on the running side of the belts (e.g. V-ribbed profiles) or anti-friction impregnations always enable perfect solutions to problems for all types of difficult materials.

Grooves offer the possibility of achieving a good frictional connection with particularly smooth material to be pulled without increasing the contact pressure. They can be designed as V-, rectangular or U-shaped grooves

Our corrugated tape features a unique structure that absorbs shocks and vibrations during transportation or processing to ensure maximum product safety. Thanks to its special construction, our corrugated tape minimizes the risk of damage and maintains the quality and freshness of your products.

Spindelband

Maschinenband

Druckdecke

Stanzband

Kurvenband

Abzugriemen

Wellband