Straps

Straps are easy to use. In different versions, they optimize drive and transport processes in many industries.

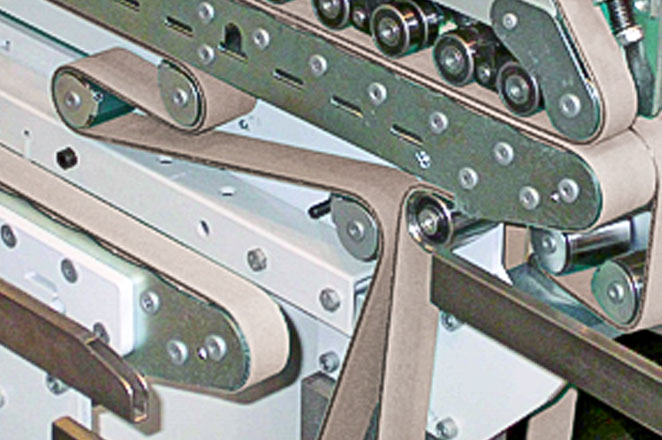

The drive belts are custom-made to meet the specific requirements of individual industries, applications or machine designs. We offer three different tensile layer materials, which are used in different concepts in open drives, tangential drives, multi-roller drives, roller conveyor drives or for double-sided power transmission.

Round belts are highly flexible and can be bent in all directions for use on angular drives. They can be used for both transport and drive applications. Due to their elasticity, round belts can be installed without a tensioning device. This enables a compact mechanical design. In addition, the elasticity increases safety, as shocks are dampened in the event of short-term overloads. Round belts are extremely resistant.

The physical and chemical properties of round belts are exceptional in many areas: their hydrolysis resistance far exceeds that of most polyurethane elastomers. As a result, SwissBeltService round belts are resistant to water, oils, grease and petrol.

Thanks to their tight cross-sectional tolerances, the round belts ensure uniform power transmission. The PU and TPE products are available in several Shore hardness grades and different surfaces (smooth, rough) to ensure optimal drive and transport properties as well as a long service life. Depending on the area of application and application, the round belts can be reinforced with different tension members (polyester, aramid, steel and weldable glass fibre PU).

profiles).

Coatings and finishing:

A wide range of coatings that provide the necessary properties to transport your product effectively. The selection of the coating material and the suitable surface structure depends on the specific application and the nature of the goods being transported.

SwissBeltService offers a comprehensive range of belts made of different materials for a wide range of folding carton applications. The belts are characterized by excellent flexural exchange properties, high abrasion resistance, excellent dimensional stability, constant and secure adhesion as well as precise folding, leaving no marks on the transported goods.

The V-belt is the best-known representative of the drive belts. It is mainly used in mechanical

engineering, in industry, in motor vehicles or in household washing machines. V-belts are oiland

heat-resistant up to approx. 70 °C, electrically conductive and dust-protected as standard.

There is no special marking.

Mechanical engineering

Heavy-duty belts can withstand extreme conditions. Large construction machines, stone crushers, cement mixers, fans, the automotive industry: Wherever dust, heat, cold, aggressive chemicals or enormous speeds put the material to the test, the V-belt shows its strengths.

Household appliances

From 0 to 100 at the touch of a button: The household appliance industry has been relying on Vbelts and V-ribbed belts for decades. Thanks to their enormous tensile strength, they reliably rev up washing machines, dryers, vacuum cleaners and kitchen appliances. Even at high speeds, Vbelts run with low vibration and whisper quietly.

Agricultural machinery

Whether combine harvesters, tractors or shredders – high-performance belts tirelessly do their job here: extremely smooth running even at constantly changing speeds, loss-free power transmission, robustness and environmental friendliness.

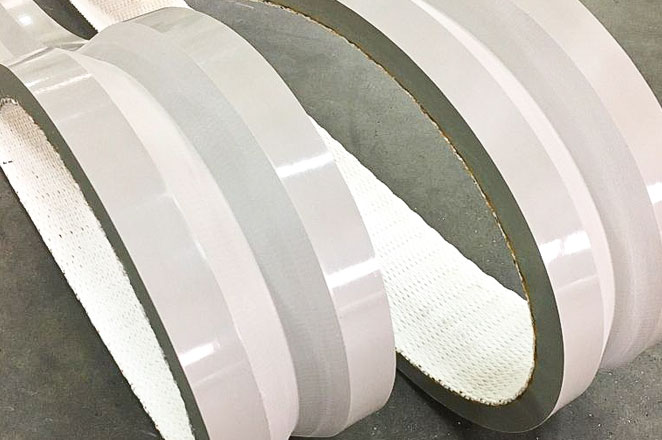

SwissBeltService take-off belts with backing coatings made of PVC, PU, rubber or silicone have been successfully used for years in the profile and plastic extrusion industry as well as in the cable, pipe and wire industry. The material structure of our take-off belts always corresponds to the latest experience and requirements of our customers. SBS lanyards feature endlessly

woven/wound seamless tension members. This results in excellent running properties and the long service life of our products. For exceptional applications, we also offer special coatings with processing according to your wishes.

Quality in detail that pays off

The endlessly woven/wound polyester inserts of our take-off belts create great flexibility and high dimensional accuracy, which enable them to be used even with small deflections.

always enable flawless solutions for difficult take-off material of all kinds.

Grooves offer the possibility of achieving a good frictional connection without increasing the contact pressure for particularly smooth take-offs. They can be designed as V-shaped, rectangular or U-shaped grooves.

Advantages of our trigger belts:

- without connection

- flexibility and dimensional accuracy

- low length tolerances

- maximum service life

- excellent running characteristics even at high belt speeds

- high coefficient of friction between belt and take-off material

- homogeneous surface without hardening and thickening

- resistant to oils and greases

Drive Belt

Extruded round belts

SYNC-timing belt

Folding saddle strap

V-belt

Trigger strap